# The Solution of Steel Coil Stretch Wrapper Loading and Unloading by Trolley

In the world of industrial packaging, steel coil stretch wrapping is an essential process to protect and secure steel coils during transportation and storage. This process involves the use of specialized equipment, such as coil wrapping machines and trolleys, to ensure the coils are properly wrapped and loaded onto pallets.

## Steel Coil Stretch Wrapper Loading and Unloading Process

The loading and unloading of steel coils using trolleys is a widely adopted method in the industry due to its efficiency and effectiveness. This process involves a series of steps that ensure the safe and secure handling of steel coils.

### Step 1: Preparation

Before the loading and unloading process begins, it is important to prepare the trolley and the coil wrapping machine. The trolley should be inspected for any damages or defects that could compromise the safety of the coils. The coil wrapping machine should also be checked to ensure it is in proper working condition.

### Step 2: Loading

To load the steel coils onto the trolley, a forklift or overhead crane is typically used to lift the coils and place them onto the trolley. The trolley is designed with a secure platform that can hold multiple coils at once, depending on its capacity.

### Step 3: Wrapping

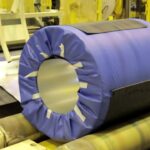

Once the steel coils are loaded onto the trolley, the coil wrapping machine comes into play. This machine is specifically designed to wrap the coils with a protective film or stretch wrap. The film is tightly wound around the coils, providing stability and protection during transportation and storage.

### Step 4: Unloading

When it comes to unloading the wrapped steel coils from the trolley, the process is essentially the reverse of the loading process. The trolley is positioned near the designated area for unloading, and the coils are carefully lifted off the trolley using a forklift or overhead crane.

## The Benefits of Using a Trolley for Steel Coil Stretch Wrapper Loading and Unloading

Using a trolley for loading and unloading steel coils offers several advantages over other methods. Here are some of the key benefits:

1. Efficiency: The use of a trolley streamlines the loading and unloading process, making it quicker and more efficient. This saves time and labor costs for businesses.

2. Safety: Trolleys are designed with safety features that ensure the proper handling of steel coils. This minimizes the risk of accidents or injuries during the loading and unloading process.

3. Versatility: Trolleys can be customized to accommodate different sizes and weights of steel coils. This makes them suitable for a wide range of applications in various industries.

4. Cost-effective: Trolleys are a cost-effective solution for steel coil loading and unloading. They require minimal maintenance and can be used for long periods without significant wear and tear.

## The Importance of Coil Wrapping Machines in the Loading and Unloading Process

Coil wrapping machines play a crucial role in the steel coil stretch wrapper loading and unloading process. These machines are designed to automate the wrapping process, ensuring consistency and efficiency. Here are some key features of coil wrapping machines:

– Automatic film feeding: Coil wrapping machines are equipped with automatic film feeding systems that ensure a continuous supply of film during the wrapping process.

– Adjustable tension control: The tension of the film can be easily adjusted to suit the specific requirements of different coil sizes and weights. This ensures a secure and tight wrap around the coils.

– Programmable controls: Coil wrapping machines are equipped with programmable controls that allow operators to set specific wrapping parameters, such as the number of revolutions and the overlap of the film.

– Safety features: Coil wrapping machines are designed with safety features, such as emergency stop buttons and safety sensors, to prevent accidents and injuries during operation.

## The Patent and Knowledge of Coil Wrapping Machines

In the world of coil wrapping machines, there are several patents and innovations that have revolutionized the industry. These patents cover various aspects of the machine’s design, functionality, and performance. Some key knowledge related to coil wrapping machines includes:

– Film stretching technology: Many coil wrapping machines use advanced film stretching technology to ensure a secure and tight wrap around the steel coils. This technology helps to minimize film usage and reduce costs.

– Automatic film cutting and sealing: Some coil wrapping machines are equipped with automatic film cutting and sealing systems. This eliminates the need for manual intervention and ensures a neat and professional finish.

– Remote control and monitoring: Certain coil wrapping machines offer remote control and monitoring capabilities. This allows operators to control and monitor the machine’s performance from a centralized location, improving efficiency and productivity.

## Check the Coil Packing Solution with Leading Manufacturer

If you are in need of a professional and reliable coil packing solution, look no further. We are a leading manufacturer in the industry, specializing in steel coil stretch wrapper loading and unloading solutions. Our products are designed to meet the highest standards of quality and efficiency, ensuring the safe and secure handling of steel coils.

Contact us today to learn more about our coil wrapping machines and how they can benefit your business. Our team of experts is ready to provide you with the best solution tailored to your specific needs.

**Check the coil packing solution with the leading manufacturer for the professional solution just here:** [Insert your call-to-action here]

With our expertise and cutting-edge technology, we guarantee to optimize your coil packaging process and enhance your overall efficiency. Don’t miss out on this opportunity to revolutionize your steel coil loading and unloading operations. Contact us now! Coil Wrapping machine