Height of the ring centre can be adjusted according to the diameter of the product; *Material tension can be adjusted automatically. Each bundle weight should be no more than 4t according to relevant standards and deign requirements. Therefore, for tubes of different diameters, it is vital to arrange reasonable tube numbers and weight scopes. Based on tube specifications and length, the computer system in the forming equipment automatically calculates tube weight and displays optional bundle shapes on the monitoring interface. Options are also available for tubes that need special treatment. After a certain option is picked, bundles can be formed automatically.4 Descriptions of Functions4.1 Loading, counting, aligning, tube-layer forming and forming mechanism

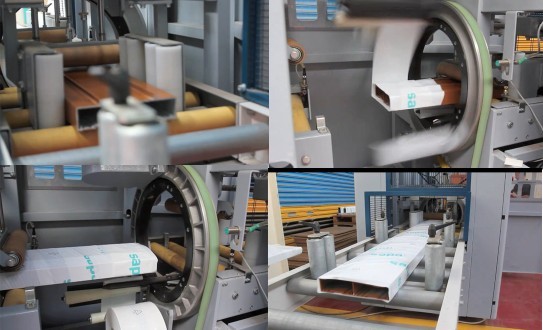

The electrical devices are installed on mounting plates in closed cabinets, protection degree IP20, designed in form 1 based on EN 60439-1. Each cabinet has a designation label on the door with the appropriate location indicator. The bundle conveying roller way, shown in Picture 4, is driven by reducer motor. The roller way, together with rollers at both sides of forming-bed, conveys the bundle away from the strapping position. Picture 4 Bundle Conveying Roller Way 4.4 Pneumatic System is the pneumatic system of stretch wrapper consists of the following parts.Air supplier processing unit, including pressure gauge, water and oil filter and switch valve ?? High automation level. The equipment is driven by servo controller and transducer controller. Siemens PLC and UP PC monitoring software are combined fairly well in the control system.Steady and reliable system. Equipped with parts and components of world famous brands, the control system is optimized subject to different situations. Easy and convenient operation. The operating interface of the monitoring software is designed according to user’s requirements. By setting tube bundles parameters in interface, operator can fulfill different contract tasks.

The electrical devices are installed on mounting plates in closed cabinets, protection degree IP20, designed in form 1 based on EN 60439-1. Each cabinet has a designation label on the door with the appropriate location indicator. The bundle conveying roller way, shown in Picture 4, is driven by reducer motor. The roller way, together with rollers at both sides of forming-bed, conveys the bundle away from the strapping position. Picture 4 Bundle Conveying Roller Way 4.4 Pneumatic System is the pneumatic system of stretch wrapper consists of the following parts.Air supplier processing unit, including pressure gauge, water and oil filter and switch valve ?? High automation level. The equipment is driven by servo controller and transducer controller. Siemens PLC and UP PC monitoring software are combined fairly well in the control system.Steady and reliable system. Equipped with parts and components of world famous brands, the control system is optimized subject to different situations. Easy and convenient operation. The operating interface of the monitoring software is designed according to user’s requirements. By setting tube bundles parameters in interface, operator can fulfill different contract tasks.

-

- the function of Pipe packaging line a) Excellent collections. Well-known brands are adopted for main components. – Adjustable Film Roping 膜可调节 … …

- the function of PPR/PVC Pipe bundling machine offering individual content articles to a conveyor program; The object is actually achieved by an equipment for launching a load provider with packaging units developing a load bunch, comprising handling and assistance means, by way of which a packaging unit to be loaded is actually supported from below throughout the operation associated with loading from a feed device onto the fill stack and which are created so as to deposit the packing unit from any selectable spatial position on the fill stack. …

- How to find Pipe coil wrapping machine Inspection and acceptance have to be carried out with corresponding standards, so as to assure fairness and rationality, to clarify responsibilities and to protect interests of both parties.Main standards of inspection and acceptance are as follows.Contract signed by Seller and Buyer Technical Annex signed by Seller and Buyer Manufacture drawings, manufacture supervision report and record, inspection and test report before delivery, running test report and unpack report, etc. Other standards approbated by both Seller and Buyer.4.3 Content of inspection and acceptance 1-5. PLC can store 99 kinds of wire reel specification, when need change wire reel specification, only need to read stored specifications.

- mould tilter 4.6.5 In case the inspection and acceptance does not meet relevant conditions or fails, the team has to prepare and re-start the procedure. 1.2.6 Manual operations: Manual operations have higher priority than auto-operation. Manual operations by buttons are allowed on dominating and assisting machineries except for auto-operation station.1.2.7 Communication: This equipment is expected to communicate with UP PC. It is able to exchange necessary operational and technical information with other working stations on the production line. For instance, it can receive ..

- the function of Wire wrapping machine placing the containers onto pallets in the palletizer, different sized containers becoming placeable on a exact same pallet by the palletizer. ?? Purchasing spare parts list, in duplicate Accompanied spare parts list (mechanical and electrical), in duplicate

- How to operating Automatic packing line Still another object of the present invention is to provide a combined system as well as method with multi-pack capabilities. ?? Air passage components, including break valve, pressure reducing valve, throttle, supercharger, muffle, air pipes, and pipe joints, etc.

- the function of Orbital wrapper transporting the person articles on the conveyor system to a packaging subsystem; 1-4.wire reel weight:max.35kg1-6.PVC/PE/PP film size:thickness:0.03-0.07mm, width:40-50mm

- the function of Automatic pallet wrapping machine d) PLC&HMI program control.e) Manual and automatic working mode can be choosing. The pallet wrapping machine standard configuration are listed below for pallet wrapping machine. (Please, contact your sales representative for other configurations available) Film 500mm wide x 76mm diameter capacity Type of the pre-stretching strain film. The pallet wrapping solution with semi auto turntable. …

- How to operating Steel coil wrapping machine Nevertheless these and other objects of the present creation are satisfied by a way of avoiding warehousing of palletized articles including the steps associated with: 2-10.switch and meter on operation panel:touch screen,speed-adjust button, emergent switch … …

- Rotate arm wrapping machine release means for giving articles in the elevators towards the respective at least one lane. 4-4.cutter:adopting air pressure cutter system, automatic cutting after reaching wrapping material length, cutter can cut PVC,PP, PE braiding band and paper etc wrapping material.4-5.clamp band device:automatic clamp band and pull band when wrapping materials are delivered to indication point, automatically get-back after winding 1 coil and automatic let go band when winding to pre-set coil .

- How to operating Wire wrapping machine The Chinese rotate ring stretch wrapper design with ring rotated is a stretch wrapper fully automatic palette that features the latest technology and reliable method. Wrap film is set in the ring and turned fast. The ring is up and down for the packing of pallets according to control program. The palette remains stationary is a method of… *The turning ring is controlled by a converter. Overlap rate can be adjusted according to the requirement; .

- the feacture of the hydraulic tilter Computer control traverse, servo motor drives, 4-3.portal cutter: 4-4.cutter:adopting air pressure cutter system, automatic cutting after reaching wrapping material length, cutter can cut PVC,PP, PE braiding band and paper etc wrapping material.4-5.clamp band device:automatic clamp band and pull band when wrapping materials are delivered to indication point, automatically get-back after winding 1 coil and automatic let go band when winding to pre-set coil .

- How to find 2-9.electric loop control:Graphic operator interface(PLC) With regard to loading laterally enclosed load carriers, for example boxes, storage containers or mesh boxes, the load-carrier tilting device may be provided, by means of which the enclosed fill carrier is tilted at the.g. through 90 degree in a ahead direction in order that it may be packed ???from above??à by the loading device according to the invention. In a corresponding method a packing-unit tilting device is then preferably provided upstream of the launching apparatus with regard to tilting the packing units through 90 degrees depending on the determined launching configuration. .

- Coil wrapper *Adopting PLC&HMI makes the machine smarter.*Double-ring & double-rub wheel devices make the work safer, more stable and efficient; The conveying roller way is, on one hand, designed to be a position