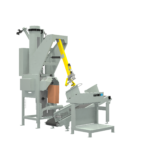

An automatic gross weight bagging machine that uses fluidization to fill valve bags with powdery or low granulometry products is a type of automated packaging system that is designed to efficiently and accurately fill bags with a specific weight of product. This type of machine typically includes a single robotic arm that is used to feed multiple filling points, which can be used to fill a number of bags simultaneously.

To use this type of machine, the operator first places empty valve bags on the filling points. The robotic arm then picks up the product from a hopper or other storage container and uses fluidization to evenly distribute the product into the bags. The machine is equipped with sensors and controls that ensure that the correct weight of product is dispensed into each bag.

Once the bags are filled to the desired weight, the machine seals the bags and removes them from the filling points. The filled bags can then be transported to other areas of the packaging facility for further processing or shipped directly to customers.

Overall, an automatic gross weight bagging machine that uses fluidization is a highly efficient and accurate way to package powdery or low granulometry products into valve bags. It can significantly reduce the time and effort required to package these types of products, making it an attractive option for many businesses.