Chinese stretch hood machine This is Chinese stretch hood system, it is equipment with stretch hood working without heat, represents a coherent development of the technology of packing units loaded on pallets. To achieve this goal, we have properly assembled different functional modules working in continuous exercise, obtaining a compact high capacity unit. The machine and its technology are suitable… 19. The strapping and wrapping machine associated with claim 18, wherein the actual loading aid encloses three sides of the load stack. – UHMW-PE Glides on 3/8″ CRS Ways (No Maintenance Lifetime Warranty)Film Tail Treatment

?? To automatically identify incorrect information and give an alarm. Rotate arm stretch wrapperThe rotate arm stretch wrapping machine is used to pack the goods in the conveyor with PE stretch film, which makes stable products, more ordained; also resistant to water and dust. And may decrease the density of labor; improve the work efficiency, by the It is a perfect packing equipment and is ideal for plants modernized in industries…. We offer innovative and sustainable pallet stretch wrapping machine and stretch wrapper to help enterprise-level companies enhance their bottom-line performance. These highly efficient stretch wrapping solutions and service include designing presentation and production fulfillment, installation, and training. To devoted pallet load logistics solutions and statistics, we‘ ve got rich experience in what must be done being your single source for innovative end-line pallet packaging..Tilter is mainly for heavy coil turning 90 degrees. The tilter can be connected to slitting ing and coil car. It is widely used in industry, metallurgy, metal, stamping mould manufacturing, paper making, steel, core, barrels, etc. Double chain, the special transmission. a palletizer for palletizing the packs of articles from both the load up supply as well as from the product packaging subsystem, packs from the packaging subsystem and from the load up supply being placeable on a exact same pallet by the palletizer; and

?? To automatically identify incorrect information and give an alarm. Rotate arm stretch wrapperThe rotate arm stretch wrapping machine is used to pack the goods in the conveyor with PE stretch film, which makes stable products, more ordained; also resistant to water and dust. And may decrease the density of labor; improve the work efficiency, by the It is a perfect packing equipment and is ideal for plants modernized in industries…. We offer innovative and sustainable pallet stretch wrapping machine and stretch wrapper to help enterprise-level companies enhance their bottom-line performance. These highly efficient stretch wrapping solutions and service include designing presentation and production fulfillment, installation, and training. To devoted pallet load logistics solutions and statistics, we‘ ve got rich experience in what must be done being your single source for innovative end-line pallet packaging..Tilter is mainly for heavy coil turning 90 degrees. The tilter can be connected to slitting ing and coil car. It is widely used in industry, metallurgy, metal, stamping mould manufacturing, paper making, steel, core, barrels, etc. Double chain, the special transmission. a palletizer for palletizing the packs of articles from both the load up supply as well as from the product packaging subsystem, packs from the packaging subsystem and from the load up supply being placeable on a exact same pallet by the palletizer; and

-

- Bearing wrapping machine Inspection and acceptance have to be carried out with corresponding standards, so as to assure fairness and rationality, to clarify responsibilities and to protect interests of both parties.Main standards of inspection and acceptance are as follows.Contract signed by Seller and Buyer Technical Annex signed by Seller and Buyer Manufacture drawings, manufacture supervision report and record, inspection and test report before delivery, running test report and unpack report, etc. Other standards approbated by both Seller and Buyer.4.3 Content of inspection and acceptance 23. The tools of claim 16 additional comprising the load-carrier changing device for exchanging a loaded load provider for an vacant load provider. … …

- the technical data of Wire wrapping machine New capacity and efficiency improvements have been made to the STRETCH WRAPPER AND inline stacking and banding system from Wexler; unit is now provided with a glue applicator for maximum holding force between slippery products.International Corporation manufactures specialized machinery for the movement and precise orientation of containers on packaging lines. CSS products include timing screws, metering systems, combiners, dividers, diverters for base coding/bottom inspection, change parts (including stars, guides and hardware) and modular drive units. Using the company motto “timing is everything”, CSS has got the practical engineering capabilities to solve everyday operating issues that slow down performance and erode profits. All CSS products are manufactured to facilitate quick changeover and therefore are pretested prior to shipment to make sure smooth operation in the field. Key CSS personnel have more than one hundred and twenty-five years of experience. To see our products functioning visit our website a completely automatic, inline solution for products of varying sizes and shapes, with an increase of processing speeds of 60-120 products/min. building After being received by an elevating conveyor belt, medium difficulty downstacker transports product to be stacked, aligned and ultra-sonically banded with paper, clear poly film or custom printed materials for branding. The downstacker allows for fluent, nonstop production. A newly available glue applicator option maximizes efficiency by supporting the holding force between slippery products. 1-3.wire reel size:outside diameter:320-600mm; inside diameter:200mm(min);height:90-180mm …

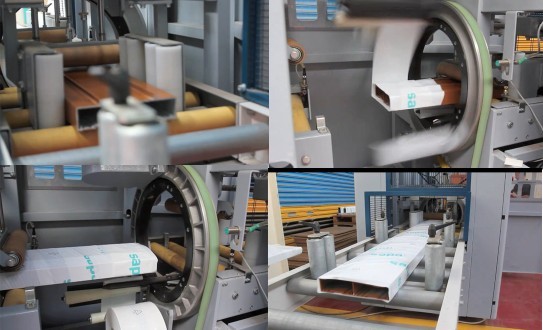

- what is the Hose wrapping machine n) Pipe are paralleled in strapped bundle. Bundle Size: Length:4000mm and 6000mm The orbital wrapper is equipment for door, window, profile stretch wrapping. Double-ring & double-rub wheel devices make working more safe stable & energetic. Designing for door and window, profile and board Friction between driving wheels and ring is adjustable.Speed of the ring is adjustable by inverter.Soft start and start with guide for protect operator.

- the feacture of the Pipe coil wrapping machine Additional scope of applicability of the present invention will become apparent from the comprehensive description given hereinafter. However, it should be understood the detailed explanation and specific good examples, while showing preferred embodiments of the invention, are given by way of illustration only, since various modifications and modifications within the spirit and range of the creation will become apparent to those skilled in the art from this comprehensive description. 2-10.switch and meter on operation panel:touch screen,speed-adjust button, emergent switch ..

- the feacture of the Automatic pallet wrapping machine supplying a pack supply separate from the product packaging subsystem; Loading the load carriers and/or pallets with the content articles, which usually take the type of packing models or collis (e.g. card board boxes or shrink-wrapped product packs), has formerly been done mostly manually. Building up such a load bunch on a pallet needs a lot of skill in order on the one hand to form a steady loading stack, which with regard to transportation is wrapped at the.g. within stabilizing movie, and on the other hand to achieve optimum utilization of space so that as high a loading stack as possible with regard to transportation within the lorry. Guide pallet loading thus remains time-consuming, requires skilled and experienced workers and is a factor restricting the success of the strategies system. The manual launching of fill carriers with occasionally heavy packing models under anatomically unfavourable problems is furthermore bad for the health of the workers involved in loading.

.jpg)

- the function of Spiral wrapping machine We delivery, and electrical control system mechanism per your requirement. The automatic coil packaging line of collection of material for packing one by one from the pendant turnstile.

- the technical data of Wire wrapping machine The present invention relates to a method and method for order packing to form a combined pallet and a mixed multi-pack. In addition, the present invention pertains to a system and method for reducing storage needs and for forming a design in a bunch of content articles. The present program and technique are considered for use along with beverage containers.2. Description of the Background Art Main Parts List:

- the technical data of Coil tilter *Separate control panel makes operation & maintenance easily; …

- Pipe packaging line Additional scope of applicability of the present invention will become apparent from the comprehensive description given hereinafter. However, it should be understood the detailed explanation and specific good examples, while showing preferred embodiments of the invention, are given by way of illustration only, since various modifications and modifications within the spirit and range of the creation will become apparent to those skilled in the art from this comprehensive description. 2 The machine frame structure made from carbon steel. Surface spray painted ..Turning cycle made of forged aluminum material ,light and sturdy … …

- PPR/PVC Pipe bundling machine production line and sharing products information for automatic packaging. The automatic packing line will be designed per different To be able to check the launching operation, the movable reader, e.g. by means of laser treatment, is ideally provided for detecting the immediate height of the load bunch.Once a fill carrier is actually full, it is exchanged ideally by means of a load-carrier altering device for a fresh, empty load provider. .

- How to find Coil Master The orbital wrapper is equipment for door, window, profile stretch wrapping. Double-ring & double-rub wheel devices make working more safe stable & energetic. Designing for door and window, profile and board Friction between driving wheels and ring is adjustable.Speed of the ring is adjustable by inverter.Soft start and start with guide for protect operator. The orbital wrapper is equipment for door, window, profile stretch wrapping. Double-ring & double-rub wheel devices make working more safe stable & energetic. Designing for door and window, profile and board Friction between driving wheels and ring is adjustable.Speed of the ring is adjustable by inverter.Soft start and start with guide for protect operator. .

- the feacture of the Spiral wrapping machine Loading the load carriers and/or pallets with the content articles, which usually take the type of packing models or collis (e.g. card board boxes or shrink-wrapped product packs), has formerly been done mostly manually. Building up such a load bunch on a pallet needs a lot of skill in order on the one hand to form a steady loading stack, which with regard to transportation is wrapped at the.g. within stabilizing movie, and on the other hand to achieve optimum utilization of space so that as high a loading stack as possible with regard to transportation within the lorry. Guide pallet loading thus remains time-consuming, requires skilled and experienced workers and is a factor restricting the success of the strategies system. The manual launching of fill carriers with occasionally heavy packing models under anatomically unfavourable problems is furthermore bad for the health of the workers involved in loading. 2-6.product convey:clamp wire 2-7.overlength:unit:0.01m, automatic reduce speed when forecast .

- How to operating Copper wrapping machine Pipe orbital stretch wrapper is a kind of Orbital stretch wrapper for steel pipe Tube packing line is designed to form bundle shape before tubes are strapped. consisting of automatic forming machine, conveying roller way, a basic design of conveying equipment after strapping, and so on, is used to carry out series of tasks, mainly, single tube loading, automatic stacking to required triangle or hexagonal bundles and conveying shaped bundles to strapping position. .

- tilter and upender 1-1.can be linkage with pay-off rack and extruder line ?? To automatically collect and track tube parameters, say, attribute, weight and length, from the measuring system. Manual operation is allowed in the tracking