To automatically monitor the system working, such as working situations at each position, bundle sizes and working speed, etc. 1.2 Requirements on forming equipment To meet the requirements of Steel Tube Packaging Standards, the equipment has the following functions. Emergence stop and position locking function avoid rotation.The machine will stop automatically when turning process finished.

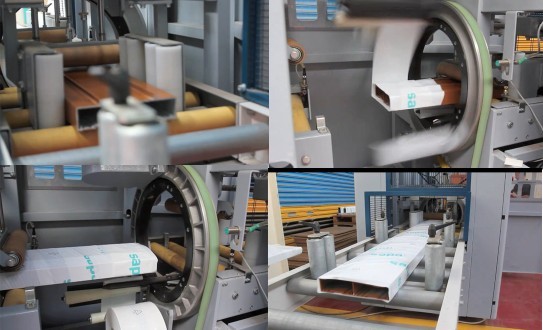

Traverse motor : Japan Mitsubishi servo 400 w motor +Mitsubishi servo inverter Horizontal Wrapping Machine is designed for all kinds of pipes ,bars,plates,floor board,aluminum,and board profile,…etc. its wide used by the advantage that completely replaces hand-wrapped packaging by reducing labor intensity, improved in packing speed, easy operation, greatly improving production efficiency from labor wrapping,. Packaging could help the object be to prevent from dust, moisture, scratch, etc.. it is Convienient and easier to be transport or in storage in good appearance. 2 wrapping material PE width 90mm,inner core 76mm,external diamter 150mmwrapping circle diameter 15-45r/min(frequenlly speed) Horizontal stretch wrapper is the machine series specialized for outer packing of horizontals objects , such as profile, door, board, copper pipes, tubes of stainless steel, aluminum tubes, plastic pipe, bars, boards, etc. Wrapped package is well protected and more orderly, nice and firm. It is easy to transport and storage.

Traverse motor : Japan Mitsubishi servo 400 w motor +Mitsubishi servo inverter Horizontal Wrapping Machine is designed for all kinds of pipes ,bars,plates,floor board,aluminum,and board profile,…etc. its wide used by the advantage that completely replaces hand-wrapped packaging by reducing labor intensity, improved in packing speed, easy operation, greatly improving production efficiency from labor wrapping,. Packaging could help the object be to prevent from dust, moisture, scratch, etc.. it is Convienient and easier to be transport or in storage in good appearance. 2 wrapping material PE width 90mm,inner core 76mm,external diamter 150mmwrapping circle diameter 15-45r/min(frequenlly speed) Horizontal stretch wrapper is the machine series specialized for outer packing of horizontals objects , such as profile, door, board, copper pipes, tubes of stainless steel, aluminum tubes, plastic pipe, bars, boards, etc. Wrapped package is well protected and more orderly, nice and firm. It is easy to transport and storage.

-

- the function of Stretch hood machine giving stock maintaining units in the storage service to a dealing with system; – Heavy Structural steel Frame construction-重型的钢结构框架结构 … …

.jpg)

- How to operating Automatic packaging line a palletizer for palletizing the packs of articles from both the load up supply as well as from the product packaging subsystem, packs from the packaging subsystem and from the load up supply being placeable on a exact same pallet by the palletizer; and ?? Communication. This system is supposed to communicate with UP PC and to transform necessary operational and technical information to the UP computer, (The key point is to communicate with previous working procedures, especially length measuring, weighing and printing procures. The measuring system provides the forming system with bundling information such as tube weight, tube length and storing information, while the forming system provides the measuring system with bundling information required.)Within 3 weeks of the coming into force of the contract, after Seller receives General chart of processing setup from Buyer, Seller delivers equipment s’ foundation lay-out drawing (including equipment dimension and max hoisting weight of installing and maintaining equipments.) (in quadruplicate) …

- what is the Coil Master (1) Seller and Buyer sign and confirm the design before equipment is put into production.

- How to operating Automatic pallet wrapping machine A system as well as method for purchase packing types a mixed pallet or a mixed multi-pack. In this system, an initial embodiment utilizes a higher volume module, a low volume module, the sorting and packing component, a prepackage component and a combined palletizer module with regard to picking, working, packaging as well as palletizing articles. In a second embodiment from the present invention, a bulk load could be fed via a carrousel to a bank of elevators. A transfer device may load different levels of the lifts which can then be relocated adjacent a discharge conveyor. The lane is supplied in this release conveyor for each from the elevators staying with you of lifts. The different levels of the elevators are positioned adjacent the lanes and may discharge articles onto the conveyor in order to form groups of the same or even different types of articles. Many different types of articles including beverage containers such as cans, bottles or beverage boxes can use this system. A pallet is formed in the same or different size package and various varieties of content articles can be placed within a single package. With regard to loading laterally enclosed load carriers, for example boxes, storage containers or mesh boxes, the load-carrier tilting device may be provided, by means of which the enclosed fill carrier is tilted at the.g. through 90 degree in a ahead direction in order that it may be packed ???from above??à by the loading device according to the invention. In a corresponding method a packing-unit tilting device is then preferably provided upstream of the launching apparatus with regard to tilting the packing units through 90 degrees depending on the determined launching configuration. ..

- How to find Horizontal stretch wrapping machine l) Strapping position reset m) The bundling system is adjustable for different pipe length. The Tube Bundles Automatic Forming and Binding Equipment is researched and developed independently Electromechanical Technology fhopepack Engineering Co., Ltd. It is a production line specially used in steel tube packaging. According to stipulations of GB/T 247-1997, API, etc., steel tubes that meet relevant requirements should be transported in bundles. Therefore, a procedure of forming and binding tube bundles is added at the end of tube production line.

- the feacture of the Bearing wrapping machine j) Automatic strapping for stringing pipes.k) Strapping belt is adjustable per requirement. The object is actually achieved by an equipment for launching a load provider with packaging units developing a load bunch, comprising handling and assistance means, by way of which a packaging unit to be loaded is actually supported from below throughout the operation associated with loading from a feed device onto the fill stack and which are created so as to deposit the packing unit from any selectable spatial position on the fill stack.

- Top supplier for Bearing wrapping machine The automatic stretch wrapping with outstanding program design. Detail perfect and expert treatment. It is a online packaging wrapper. It working without crew. The steps include the extended load, power of film, packaging, cutting, smoothing, transport It can be completed automatically.

.jpg)

- the technical data of Automatic coil packing line a conveyor program for transporting the articles from the article supply to the packaging subsystem, with regard to transporting the actual packs from the packaging subsystem to the palletizer and for transporting the packages from the load up supply towards the palletizer. 2-6.product convey:clamp wire 2-7.overlength:unit:0.01m, automatic reduce speed when forecast …

- the function of upender It is still an additional object of the present creation to provide support for marketing initiatives. Winding motor:7.5HPx4P AC motor+vector control Inverter … …

- How to operating Pipe coil wrapping machine 3-4.automatic arm device————————–1 group3-5.control and operation system————————1 group .

- How to find Horizontal stretch wrapper In order to nourish a packaging unit in a defined placement to the loading machine, the rotary apparatus for rotating the containers, which each carry a packing device, as well as a tray-vibrating device for defined positioning of the packing device on the holder are preferably provided. 2 power wheel and idler wheel with wear-resistant polyurethane and is made of 45 # carbon steel. .

.jpg)

- the feacture of the Rotate arm wrapping machine 4.1.5 Tube-layer conveyed by the folk When a layer gets to the folk starting position, the folk first lifts up, then moves forward, and reaches the position above bundle forming-bed. The folk declines, then puts the layer into the forming bed and finally withdraws. This is a layer stacking cycle. Because the folk is slightly sloped, tubes can automatically roll to the forming bed when the folk declines. 2 inverter control speed from speed 1m-4m/min,adjustable . Powerful fault detection system, fault alarm, easy maintenance .

- what is the Door packing line 4-3.automatic arm device:adopting 4 groups of electric arm to adjust, including adjusting wire reel size and collating winding center point , four shaft power clamp wire and don’t slip. Can adjust wrapping film overlap degree – Dust-tight Precious Metal Slip-ring for long reliable service .

- Top supplier for Bearing wrapping machine 1-1.can be linkage with pay-off rack and extruder line – Hinged mast for easy handling – Forklift transportable可用叉车运输 .