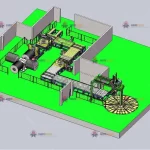

Silicone hose manufacturing encompasses an intricate process that involves meticulous hard work and precision. Beginning with selection of the finest quality silicone rubber, the process demands utmost integrity. Soon after, the selected material undergoes extrusion, a pivotal step where the silicone rubber attains the hose structure – a process facilitated by an extrusion machine.

Once formed, the hose structure is then treated to high temperatures in vulcanization, which imparts it the sturdiness it is so praised for. Notably, the usage of wrapping machines is pivotal in this step, as they aid in efficiently coiling the product, thereby ensuring uniformity and perfection. Such machines are programmable, thus capable of a variety of higher-end specifications– speaking volumes about their importance in the manufacturing process.

Once the vulcanization process is completed, it is followed by product trimming and finalizing the ends as per specified lengths. Thus, through these calculated steps, the ideal silicone hose is produced.

The hose wrapping machine holds prime importance in this production process, with its endless services. It does not simply just ensure the correct wraps per coil and facilitated handling for operators but also maintains the hygiene of the products, fosters consistency and minimizes errors. Due to these advantages, hose wrapping machines have seen a surge in demand. They offer optimum user-friendly interfaces, easy operation, and high working efficiency, making them an indispensable part of the silicone hose manufacturing process.

Find more about innovative solutions for your coil packing requirements from the industry’s top manufacturers. Exploit the opportunity to gain an upper hand with tailored and efficient harnessing techniques right now. Coil Packing Machine

"Comprehensive Guide to Silicone Hose Wrapping Production Process"

#silicone #hose #wrapping #production #process